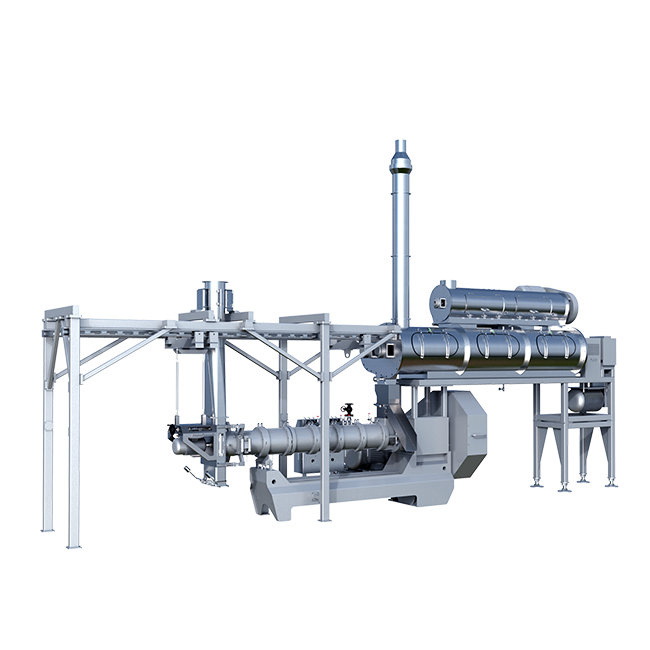

Efficiency and quality are of the utmost importance in the dynamic field of aquaculture.The FAMSUN SJPS series single-screw aquafeed extruder stands out as a game-changer, specifically designed for producing floating and sinking aquafeeds. This advanced extruder is particularly effective for freshwater floating aquafeeds and sinking shrimp feeds, delivering an impressive output of 10 to 20 tons per hour.

Superior Performance in Aquafeed Production

FAMSUN, a leader in food extruder technology, has engineered the SJPS series to meet the diverse needs of aquaculture. This single-screw extruder not only ensures high-quality feed but also enhances the nutritional value, promoting healthier fish and shrimp growth. Its innovative design allows for precise control over the extrusion process, resulting in consistent feed pellets that float or sink as required.

Versatility for Different Aquaculture Needs

The versatility of the FAMSUN SJPS series single-screw aquafeed extruder makes it ideal for various aquaculture applications. Whether producing feed for freshwater species or specialized sinking feeds for shrimp, this extruder adapts to different formulations. This flexibility is crucial for aquaculture businesses aiming to optimize feed efficiency and reduce waste.

Energy Efficiency and Sustainability

Sustainability is a core focus in modern aquafeed production. The FAMSUN food extruder incorporates energy-efficient technologies that minimize power consumption while maximizing output. This commitment to sustainability ensures that aquaculture operations can thrive without compromising environmental responsibility.

Conclusion

In summary, the FAMSUN SJPS series single-screw aquafeed extruder is a vital asset for any aquaculture operation. Combining efficiency, versatility, and sustainability, this food extruder sets new standards in feed production, contributing to the growth of healthier aquatic species.